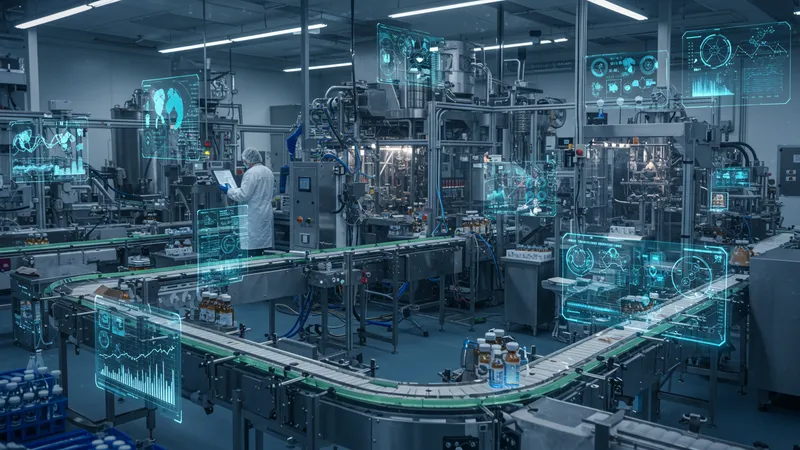

Complex scientific breakthroughs often hinge upon intricate systems humming away behind the scenes. Nowhere is this more visible than within life sciences, where modern manufacturing isn’t just about mixing chemicals – it’s about tailored processes that turn biotechnological innovations into safe, consistent products. The concept of end-to-end biotech formulation plant solutions for life sciences revolves around comprehensive systems that manage every aspect of biotech manufacturing. This includes everything from ingredient intake to formulation, quality management, filling, packaging, and regulatory documentation, all integrated seamlessly to deliver reliable results.

Such integrated solutions are designed to streamline each step in the pipeline, eliminating disconnects between process stages. Instead of patchwork fixes or isolated upgrades, end-to-end systems offer a unified, validated framework. They ensure critical compliance with international standards, support advanced analytics, and provide real-time visibility across operations. This holistic approach is raising the bar for pharmaceutical, vaccine, and biologic manufacturers worldwide.

One major advantage of adopting an end-to-end approach is the drastic reduction in production timelines. For example, a facility leveraging full automation and real-time monitoring with Sartorius BioPAT can detect and resolve process deviations hours or even days faster than traditional setups. This agility enables rapid response to changing demands—ideal for scaling up vaccine or therapeutic protein output when rapid deployment is critical.

Another strength lies in compliance management. End-to-end plant systems from companies like MilliporeSigma seamlessly integrate electronic records, batch reports, and data integrity features. This means unprecedented ease in passing strict audits from regulators such as the FDA or EMA. Automated workflows reduce the risk of human error, which translates into safer products and less downtime due to rework or investigations.

Modern facilities need agility as well as traceability, and Cytiva’s BioProcessing Automation illustrates how modular plant design allows for expansion or reconfiguration without massive new investments. This means plants can upgrade to accommodate new biotherapeutics, even switching between mammalian cell culture and microbial fermentation processes with minimal disruption.

The current generation of end-to-end solutions leans heavily on digital innovations, including cloud-based production tracking, predictive analytics for batch optimization, and Internet-of-Things (IoT) sensors for predictive maintenance. These technologies form the backbone of tomorrow’s intelligent biotech plants, bringing a level of precision and reliability once out of reach. The deeper details reveal even more valuable insights ahead as we break down how these solutions shape every major facet of life science manufacturing.

Integration is a definitive strength of end-to-end biotech formulation plant solutions. By synchronizing raw material management, compounding, formulation, fill/finish, and packaging, manufacturers create fluid operations with minimal manual intervention. This comprehensive connectivity ensures that data from every stage, from initial ingredient intake through to finished product, is accessible for real-time analysis and quality control.

For example, Sartorius BioPAT Process Control Systems utilize embedded sensors and digital process analytics, capturing thousands of data points per batch. This level of integration supports prompt interventions and deviations analysis. The result is not only increased consistency in product quality but also dramatically less wastage from batch failures or contamination.

MilliporeSigma’s Process Solutions offer harmonized platforms where all process modules—from upstream cell culture to downstream purification—communicate over a unified digital backbone. Operators benefit from centralized recipe management, electronic batch records, and interconnected quality systems, ensuring that every step is documented and controlled according to global regulatory frameworks.

The ecosystem model created by Cytiva’s BioProcessing Automation goes further. Their plug-and-play plant modules can be rapidly commissioned or swapped out, supporting both single-use and traditional stainless steel equipment. As facilities seek flexibility in an ever-changing research landscape, this integration level means new therapies can reach production faster—sometimes shaving months off regular timelines.

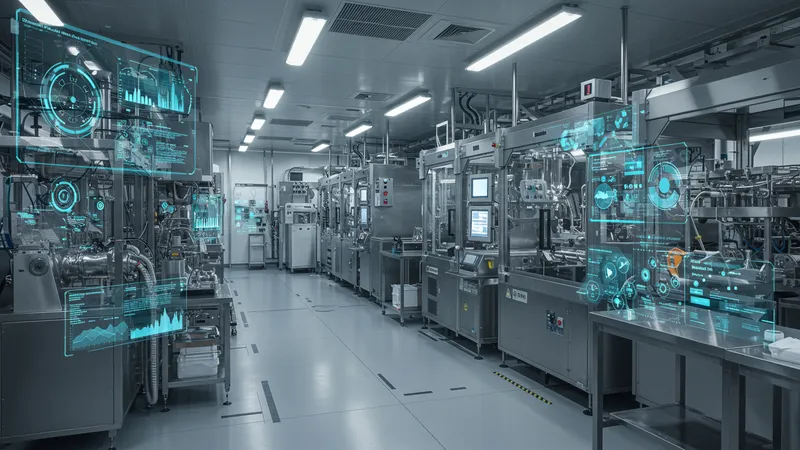

Automation stands at the heart of modern end-to-end biotech formulation systems. Platforms like Sartorius BioPAT and MilliporeSigma enable operators to regulate entire production trains—from culture growth to vial filling—via centralized HMI (human-machine interface) dashboards. Analytics engines powered by AI and machine learning identify process patterns, optimize yield, and flag issues long before they can affect quality.

Cloud-based management tools make it possible for plant managers to monitor operations remotely, tracking KPIs and intervening when predictive algorithms highlight maintenance needs or process drifts. This not only maximizes plant uptime but also allows for dynamic production scheduling across multiple product lines, a necessity for contract manufacturers.

Cytiva’s systems feature extensive automation in cleaning, sterilization, and batch changeover. This reduces manual handling, which both lowers contamination risk and enhances operator safety. With robust digital logs of all activities, compliance documentation becomes nearly automatic, further reducing administrative burdens.

Predictive maintenance—an advanced feature in today’s digital ecosystems—proactively alerts technicians to potential equipment failures. Sensors and IoT devices integrated across a formulation plant continuously feed diagnostic data into AI systems that can schedule service tasks long before actual breakdowns occur, trimming maintenance costs and production delays.

Ensuring impeccable quality and regulatory compliance is a distinguishing requirement in life sciences manufacturing. End-to-end solutions are designed with compliance at the core, embedding regulatory logic for GxP, FDA, EMA, and other guidelines directly into system workflows. This strategy facilitates adherence even as global standards evolve, reducing risk during audits and product releases.

MilliporeSigma’s digital batch records provide extensive audit trails, change control, and electronic signatures, matching regulatory requirements for data integrity. By automating documentation and deviation tracking, these solutions minimize human error and accelerate the preparation of compliance reports.

Sartorius BioPAT allows manufacturers to standardize critical process parameters, which not only enhances batch-to-batch reproducibility but also eases the validation process. Digital control over environmental monitoring, cleaning logs, and operator activities is linked, guaranteeing that all details are recorded, traceable, and ready for review.

Cytiva’s automation platforms ensure that all critical process steps—from sterilization to fill-finish—are validated by embedded sensors and reviewed through centralized control. This continuous data capture demonstrates compliance during both routine operations and in-depth regulatory audits, cementing trust among patients, physicians, and authorities.

One of the most attractive features of modern end-to-end solutions is their ability to scale and adapt to ever-changing requirements. Whether launching a new biologic or increasing batch volumes for an established therapy, flexible plant modules and digital process control are invaluable. Sartorius BioPAT offers modular add-ons, letting facilities grow infrastructure in step with R&D breakthroughs or market demand shifts.

MilliporeSigma’s approach to process solutions includes platform technologies and custom single-use assemblies. This allows startups and established enterprises alike to fine-tune their process footprints, scaling up or down as needed without a total facility overhaul—optimizing capital expense and ongoing operational costs.

Cytiva excels in agile deployment. Their projects can deploy pre-validated modules, significantly condensing timelines to operational readiness. This is crucial for emerging therapies (such as gene or cell therapies), where time-to-market is a key consideration and flexibility to adjust protocols becomes a competitive advantage.

Customization goes beyond physical hardware. Digital control architectures offer extensive recipe management, analytics customizing, and support for multi-product workflows. Such adaptability ensures continued efficiency even as portfolios diversify, helping biotech innovators stay ahead in a constantly evolving field.